Measuring commercial coffee machine motors.

Commercial coffee machine motors shown here are currently not available in the coffee shop. First of all the purpose of this post is to provide information and images relating to those products.

Estimated reading time: 5 minutes

Table of contents

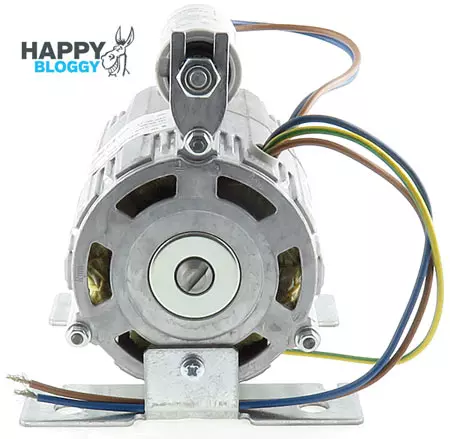

Motors vary in size, power rating, volts, revolutions per minute and more. Most noteworthy is the difference in base plate design. While a replacement motor of similar specification will often work, the fixing holes or slots may be different.

Manufacturers design base plates on commercial coffee machine motors to different standards. Fitting a replacement spare part motor therefore often requires further fabrication.

Distances between slots and holes are shown in the first table below. All dimensions are approximate, supplied for comparison purposes. Dimensions should be compared to existing parts in order to confirm compatibility.

| Motor Type | Distance between hole or slot (length ways) | Distance between hole or slot (width ways) | Diameter of hole or slot |

|---|---|---|---|

| RPM External Motor | 95mm | 86mm | 7mm |

| RPM Standard Motor | 105mm | 43mm | 7mm wide, 23mm length |

| RPM Slimline Motor | 102mm | 90mm | 10mm |

Focusing on the three main types of RPM pumps most noteworthy is one of the three being external. External pump motors being used most commonly with CMA, Astoria and Costa espresso machines.

The external motor requires a wiring loom for connection, If the loom is absent a new one needs to be fitted or made. Check the internals of the machine to see if there is a pump motor present there.

Choosing a motor

Especially relevant when choosing a replacement motor is the specification in terms of wattage and RPM if known. The closer the variables, the nearer the compatibility. A significant difference will be noted when using less or more power.

The temptation to fit a slim line motor as a replacement for s standard motor should be avoided for instance. This is because the wattage differs significantly. Performance will be incompatible or indifferent at best.

The next table illustrates variables of the models:

| Motor | Type | Volts | HZ | Watts | RPM | MF | AMP | VL |

|---|---|---|---|---|---|---|---|---|

| Standard RPM | 11002703 | 230 | 50 | 165 | 1370 | 10 | 1.6 | 450 |

| External RPM | C011527 | 230 | 50 | 245 | 1320 | 6.3 | 2.35 | 450 |

| Slimline RPM | C013726 | 220/230 | 60/50 | 120 | 1570/1320 | 6.3 | 1 | 450 |

In addition to the information shown above the table below list common manufacturers utilising motor types. Most of all note well some manufacturers use more than one type. Often dependant on the model for the coffee machine. Furthermore where available are manufacturers relevant part numbers.

| Motor | Known Compatibles |

|---|---|

| Standard RPM | BFC PART NUMBER: 5001130, BEZZERA PART NUMBER: 7742202.01 BRASILIA PART NUMBER: 00600.4.00.08, CARIMALI PART NUMBER: 95.01234 CMA PART NUMBER: 18308, CONTI PART NUMBER: 406911 ELEKTRA PART NUMBER: 00092035, EXPOBAR PART NUMBER: 60000020 GAGGIA PART NUMBER: WGA5001017000, GRIMAC PART NUMBER: GRC128 LA NUOVA ERA PART NUMBER: NE243, NE244, MAGISTER PART NUMBER: 180020 MARZOCCO PART NUMBER: L290/5, PAVONI PART NUMBER: 451039 PROMAC PART NUMBER: 34011102, RENEKA PART NUMBER: 9007914, 9007907 SAN REMO PART NUMBER: 10252086, 10252098, SIMONELLI/VICTORIA ARDUINO PART NUMBER: 04500034, SLAYER PART NUMBER: 3000058020 SPAZIALE PART NUMBER: 4641, WEGA PART NUMBER: WY18308 SOME ASCASO, AZKOYEN, CIMBALI, DALLA CORTE, FIORENZATO, MY WAY, SAECO, SYNESSO, UNIC, VIBIEMME, VICTORIA ARDUINO, VISACREM. |

| External RPM | CMA PART NUMBER: 18303, GAGGIA PART NUMBER: DM1943, MARZOCCO PART NUMBER: L290/5, SAN MARCO PART NUMBER: 108006, SAN REMO PART NUMBER: 10252099 SOME ASTORIA, BEZZERA, CMA, COSTA, GAGGIA, LA SPAZIALE , MARZOCCO |

| Slimline RPM | BFC PART NUMBER: 5001150, ECM PART NUMBER: C199900286 EXPOBAR PART NUMBER: 60000025, FRACINO PART NUMBER: FC224 PAVONI PART NUMBER: 451039, SPAZIALE PART NUMBER: 7623 SOME ECM, FUTURMAT, MAIRALI, PAVONI, WEGA. |

Faulty motors are not worth repairing, rather it is not economically viable to do so. A very noisy motor is most often on the way out. The job of the motor is simple it spins the pump and nothing else.

All three motors use a standard Fluid-o-tech PA1504 pump head, the head bolts on to the motor with the supplied clamp, which is bolted on. The shaft is flat and oblong shaped.

| External pump motor | RPM standard motor | RPM slimline motor |

|---|---|---|

| 175mm Height | 180mm Height | 143mm Height |

| 195mm Length | 165mm Length | 145mm Length |

| 125mm Width | width 125mm Body, 135mm including base | 125mm Width |

Fluid-o-tech PA1504 pump head in commercial coffee machine motors.

The Fluid-o-tech PA1504 is the most used pump head on commercial coffee machines. Utilising 3/8 inch connectors for the hoses. Most of all the flow rate is measured at 200 Litres per hour.

Pump heads are water lubricated. A pump head left unused for prolonged periods is therefore subject to fail. Pumps stored in minus temperatures will freeze, expand and consequently fail also.

Finally pump heads fail more often than motors, it is not uncommon to replace a head every 12 months on a well used machine. In addition need to adjust the pressure of an existing pump is merely an alarm signalling the imminent demise of the pump.

Now that knowledge is there and the espresso machine is all up to pressure. What about the other variables? Got to get those right.

Because we start with freshly ground coffee. We need to pay attention. Have a read and absorb related information answering the question. How to clean coffee grinders?